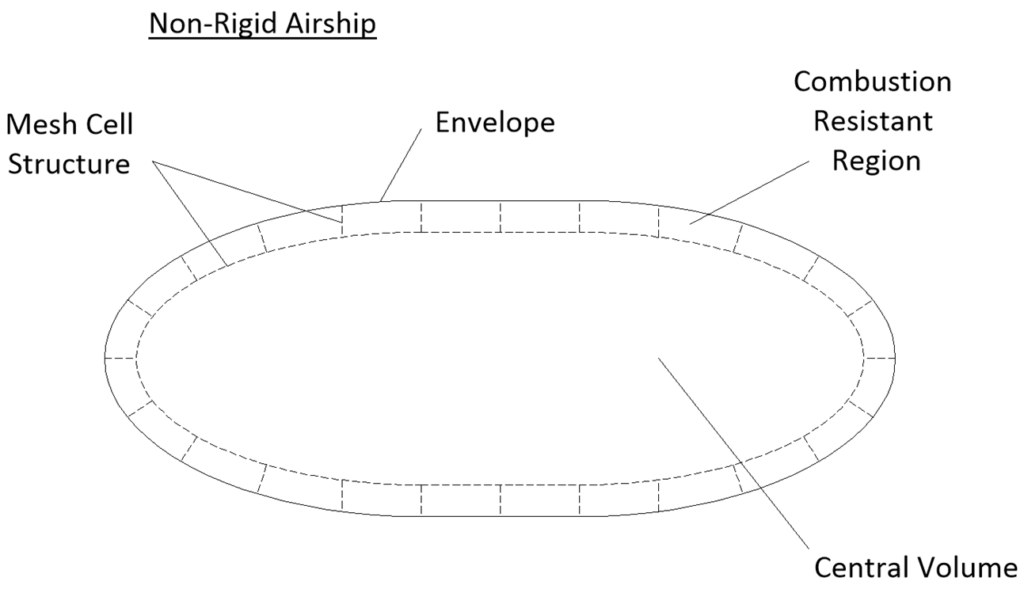

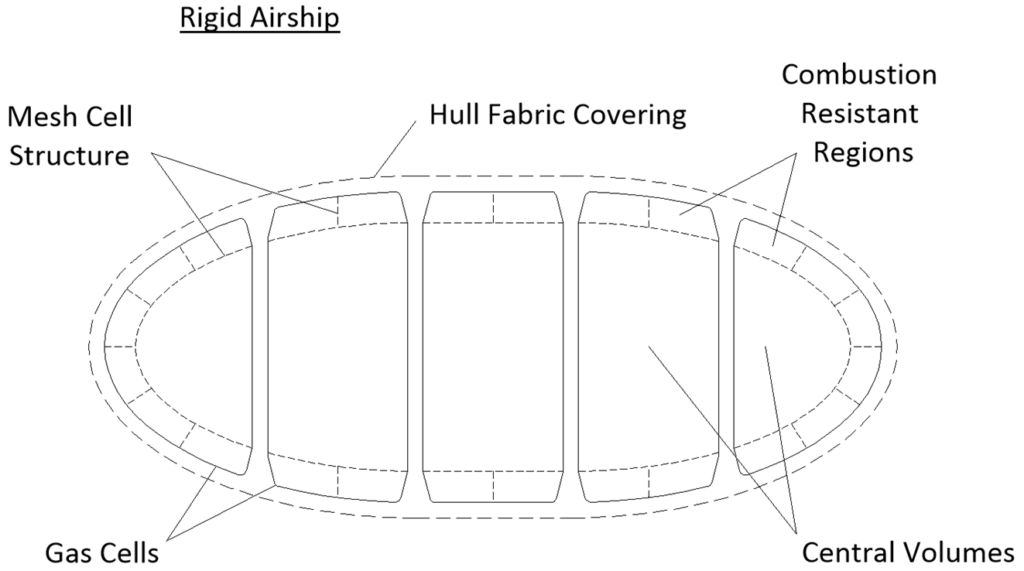

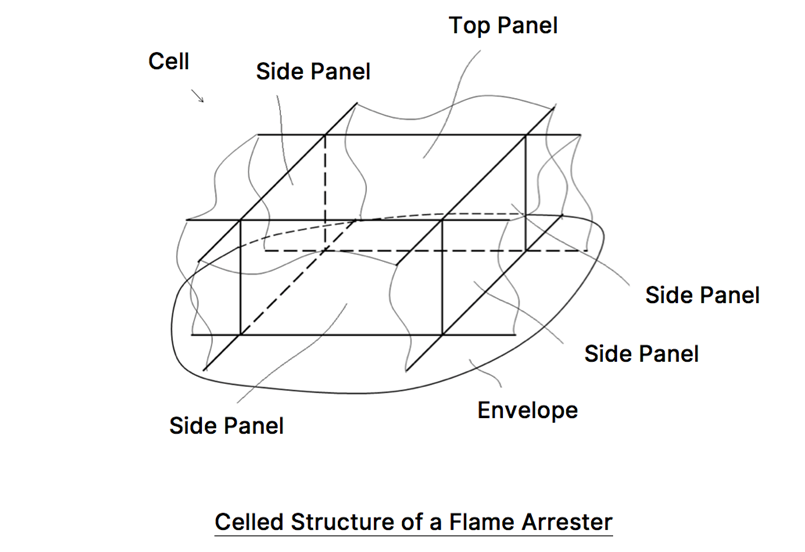

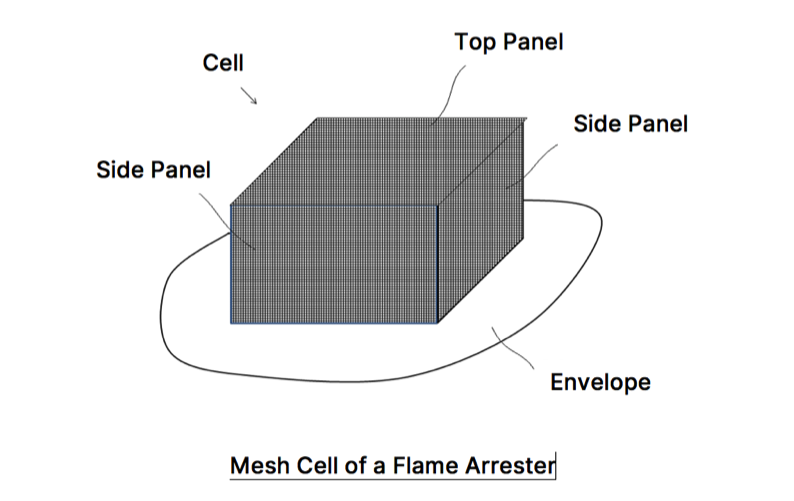

The flame arrester (see figures below) will comprise very thin mesh panels, less than 1mm thick, made from aluminium alloy and/or carbon fiber. These panels are combined to form large mesh cells, for example, length 3m, width 3m and height 2m. These mesh cells are connected to each other and to the inside surface of the airship’s envelope (for hybrid, non-rigid airships) or outer walls of gas cells (for rigid airships) to form a combustion resistant region 2m thick (or greater). This region is capable of quenching any flames within one second.

Cross-sectional views of airships filled with hydrogen

An accidental tear in the airship’s envelope or gas cells would result in air mixing with the hydrogen to make a local combustible hydrogen-air mixture. Accidental combustion of this mixture could result in flame propagation within the envelope or gas cells. However, the flame propagation would be limited to one or a few mesh cells depending on the nature of the tear. Most importantly, the central volume(s) of hydrogen, even when mixed with air, is protected from the advancing flame front.

The mesh panels ideally should quench a flame front from a worst case (“stoichiometric”) hydrogen-air mixture.

Within a mesh cell experiencing combustion: Most of the hydrogen ahead of the advancing flame front is ejected through the cell’s mesh panels by the expanded combustion products behind the flame front. So the post-combustion heat within that mesh cell is relatively low. This allows the cell’s thin mesh panels to remain functional and cool enough to avoid causing secondary ignitions. Also, the cell allows relatively free gas expansion through its mesh panels during combustion. Therefore, the thin mesh panels are not over stressed and remain structurally sound.

Progress so far

The innovation has “Patent Pending” status.

Based on previous experimentation into thin flame arresters and the proposed application for airships, the innovation is at Technology Readiness Level (TRL) 2.

Lifting Gas has been working with a leading UK university to progress this innovation to a funding application stage. A test rig design and research plan have been produced and summarised in a Statement of Work.

The test rig and research plan focus on controlled combustion of small volumes of hydrogen-air mixtures. The test rig will enable control of the flame speed that reaches small test mesh samples (as well as control of other relevant parameters).

Next Steps

Lifting Gas will partner with a UK university in order to carry out the research programme as defined in the Statement of Work. The research programme aims to take this innovation to TRL3. A funding application phase has begun. We welcome approaches from interested parties.